I’ve been waffling all over the place trying to decide on a standalone ECU for this project. I’ve looked at AEM, Link, Haltech, MoTec, Megasquirt, and probably some others. The prices range from like $1k to over $8k, and the feature set is diverse.

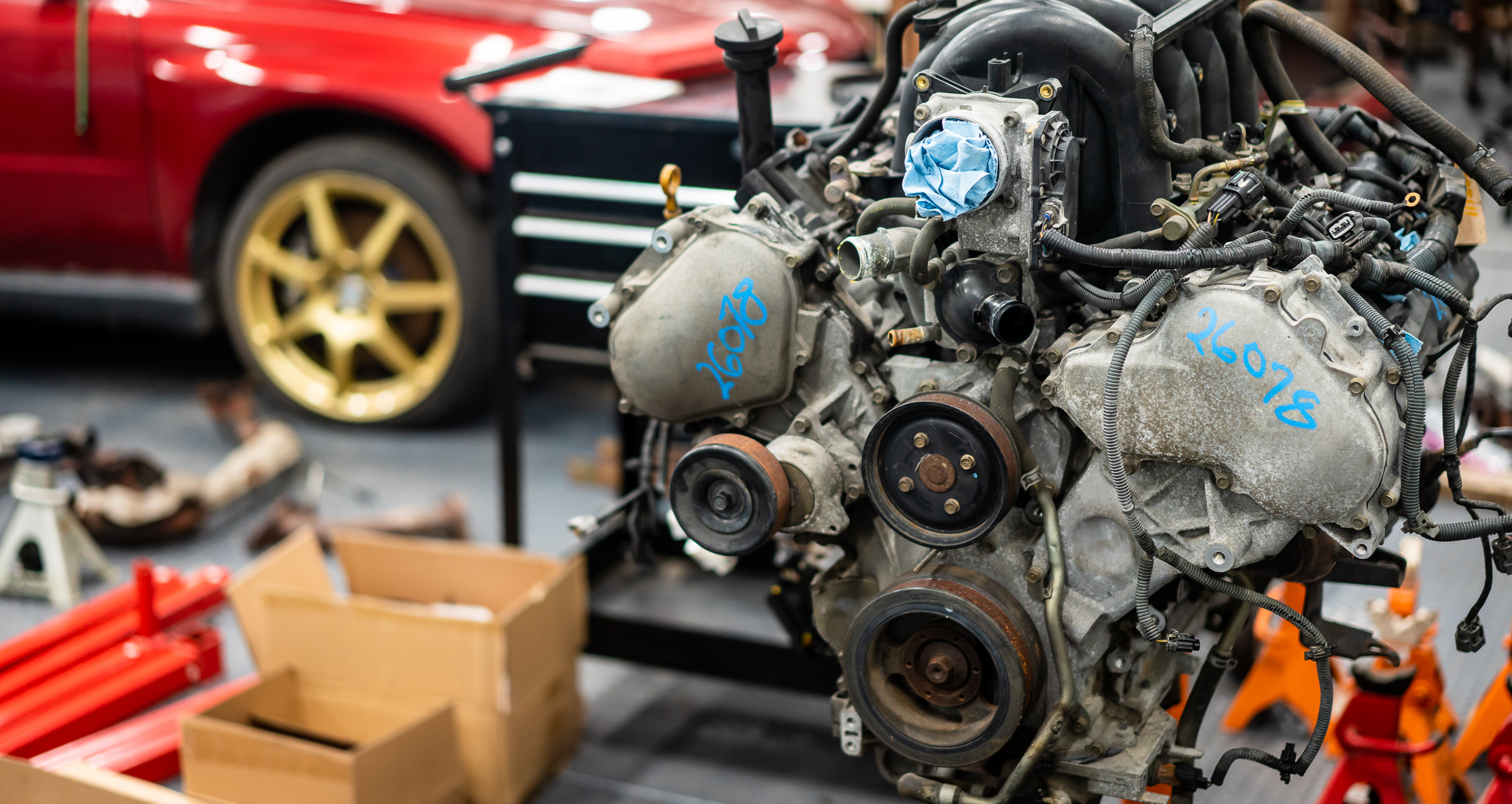

Unfortunately, there’s not a robust, clear cut, or even dirty cut, path to putting this engine on a standalone ECU. I’ve made my life a bit easier (on purpose) by not going with the variable cam version of this motor, but I’m on my own nonetheless.

The AEM Infinity seems to be getting good reviews on the hardware and some middling reviews on the software, but there are some features I really like on it, like the integrated wideband oxygen sensor controllers and lots of inputs and outputs for sensors and switches. The unit is fairly new to market, so they’re offering the full feature set at a bit of a discounted price to gain some traction.

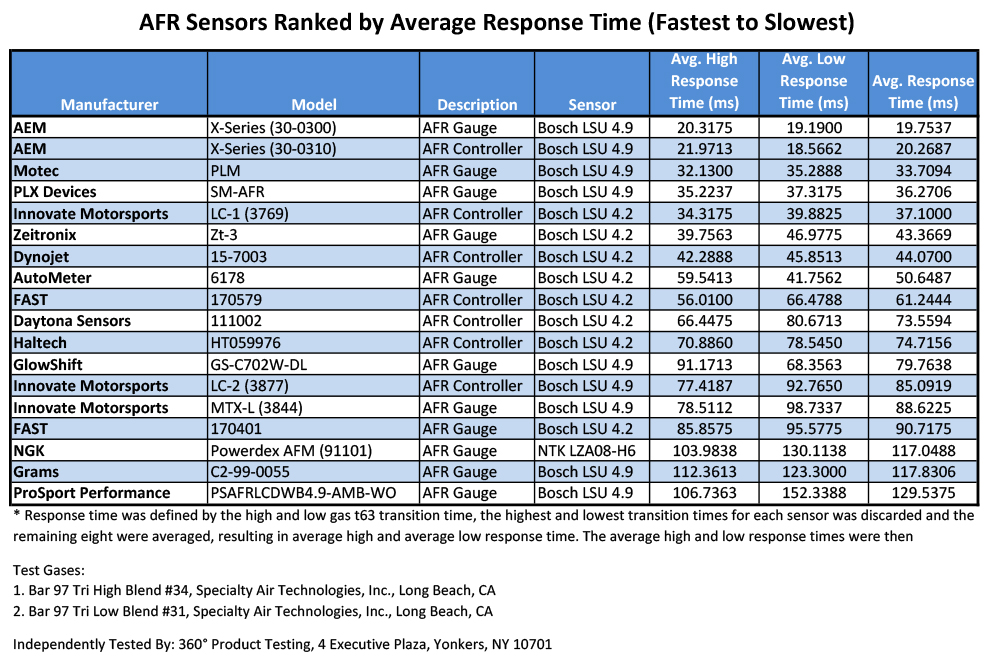

One niggling, yet important, item bothering me about the AEM Infinity 708 is the dual built-in wideband controller implementation. I really like the idea of not having to buy separate controllers for simplicity reasons, but the 708 on-board controllers use Bosch LSU 4.2 sensors. These are old sensors that have been replaced by the LSU 4.9. In fact, the 4.2 is so old, it's hard to find any modern wideband controller that uses them anymore. AEM themselves use the 4.9 in their latest-greatest "X-Series UEGO Wideband Controllers".

This led me to searching for feedback on the differences between the 4.2 and 4.9, and if they mattered.

They do. In fact, I stumbled upon a magnificently (maybe horribly, depending on how much you like electronics design) detailed wideband controller review thread. In fact, it even features a bit of a spat between an AEM engineer and the 14point7 engineer on some seriously nitty gritty design and test details.

MONSTER WIDEBAND CONTROLLER THREAD

Previously, I assumed wideband controllers were a commodity: interchangeable and equal. I learned that this is absolutely not the case; there is a serious difference in the design, implementation, and execution of these things which leads to wildly varying accuracy, response time, and longevity. Most of the controllers on the market were measured having more than 0.5 Gas AFR errors, usually to the rich side (meaning the engine was running 0.5 AFR LEANER than the controller showed).

Yikes.

The AEM X-Series was released with great fanfare and a pretty unique design; test results show that it is probably the fastest responding controller on the market with good accuracy. AEM released the results of third party testing (which they paid for) showing their controller to be the fastest by some margin:

The 14Point7 Spartan2 carries a very nice reputation for quality (backed up by a 2-yr warranty, vs 6 months for many other products; AEM = 12mo) and accuracy. 14point7 guesses they'd be in the low 40ms response time; they optimized their design for accuracy and reliability and let the response time fall where it may.

Given all of this, I considered whether it's more important to use accurate wideband controllers rather than keep everything tidy. One side benefit to this is that it would allow me to step down from the Infinity 708 controller to the 508, which saves me $1,000. The other features I would lose with this move (dual drive-by-wire, dual h-bridge, 4-wheel speed traction control, etc) are not important to me. The only thing I see that may be a bummer is that there are almost double the amount of digital and analog inputs available on the 708. I’m not sure whether the price difference is worth the extra features.

As far as wideband controllers go, the AEM X-series controllers are $235 vs the 14point7 Spartan2's $125. The added benefits of the AEM are speed and the ability to send AFR readings over AEM's CAN implementation (AEMnet), which would free up 2 analog inputs that may become scarce. Might those extra inputs be worth $110 each at some point? Given my affinity for data collection, I’m leaning towards yes, but who really knows.

Anyhow, after much deliberation and even more research, I pulled the trigger on an AEM Infinity 708 standalone ECU, along with a starter wiring harness. I want to at least try the dual onboard wideband controllers, and it has double the amount of I/O as the 508. Did I make the wrong decision? I don’t think so, obviously, but we’ll find out.

One of the big changes that needs to happen to get the motor running in stock form is to do with the crank trigger setup. The stock implementation is a giant goofy pie plate notched wheel that's bolted to the flex plate (this motor only ever came paired with an automatic) and a sensor that bolts to the transmission bellhousing. Which I don't have.

So I'm going to run a 36-1 trigger wheel with an inductive VR sensor at the crank. DIYautotune has a nice 8 1/4" wheel for cheap and I found a VR sensor on mouser that looked good on paper.

What I didn't realize is that the sensor is sized for cruise ships. The thing is absolutely massive; the nut on the threaded body needs a 27mm wrench. Whoops.

It wasn't terribly expensive, so I'll probably just keep it to practice with for now. In fact, I set up a small test to see if I could see a waveform out of it.

Unfortunately, I had no idea what I was doing, so I stopped before I accidentally sawed my sensor in half with the trigger wheel.

So I bolted it up to the crank pulley, which for some reason has 6 M6 threaded holes in the front of it.

Good lord that's ugly. Not to mention it weighs like 1.3 lbs. I'm not sure this is the final solution (in fact I'm pretty sure there's no way either of these pieces will be on the final build), but they should suffice to give me some practice with setup and programming on the new ECU.

At least that's what I'm telling myself. I sat in the car for a few minutes thinking about this whole project. I became overwhelmed so I stopped.

Small bites of the elephant and all that, I suppose.

Thanks for reading!

damen

Next Datsun Post: Engine Stand

Previous Datsun Post: Transmission Picked Up

All Datsun Posts: 600HP V8 Datsun 280Z